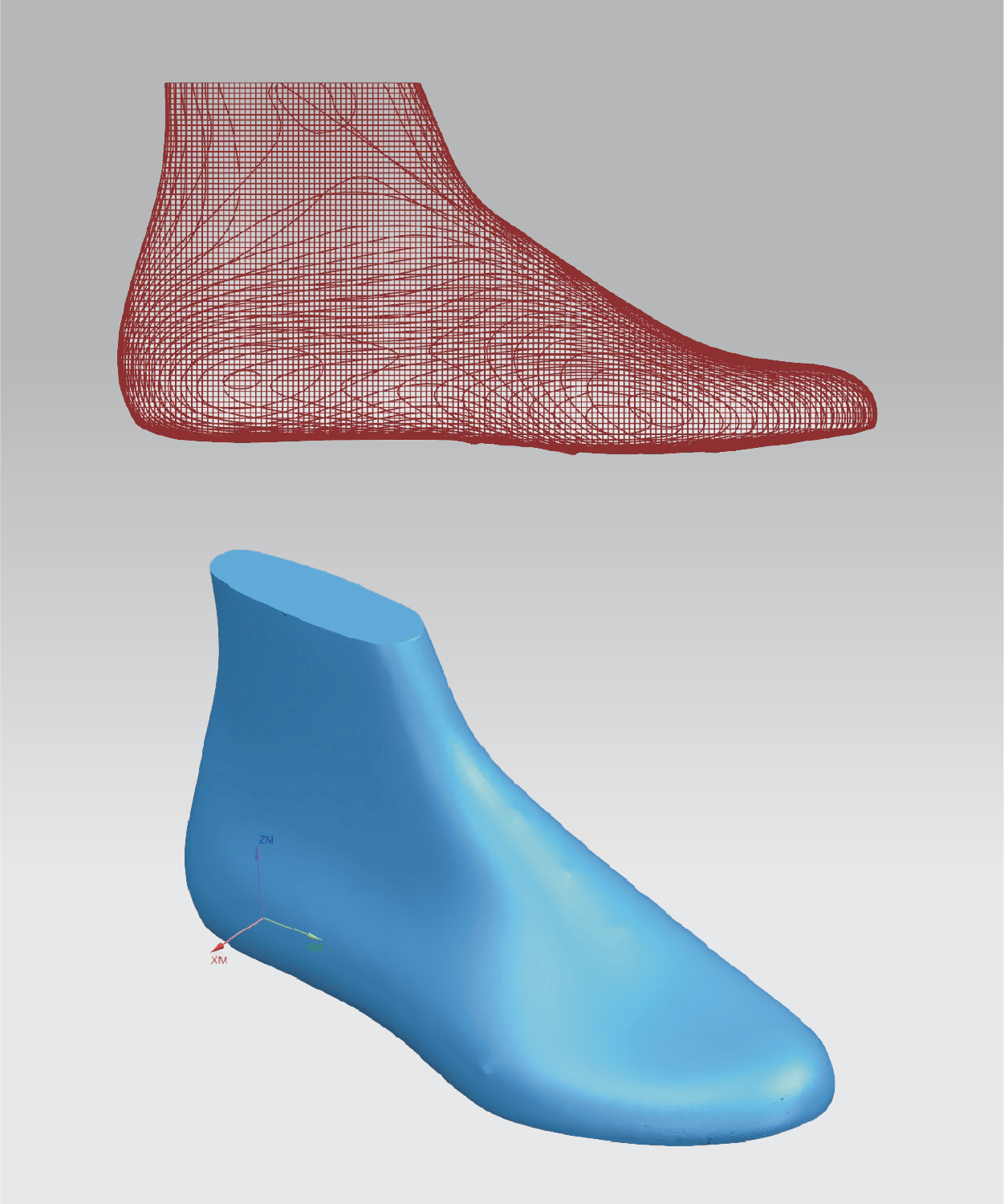

CAD CAM

With the trend of automatic production in the footwear industry, three main axes of automatic processing, engineering manufacturing and assembly design have been integrated. In 2017, the AUTO automatic last department was established, using advanced processing technology and precision machinery and equipment to meet the high-end finishing of professional diverse designs and special needs.

The inspection of the accuracy and quality of the last is meticulous, including accurate and efficient reproducibility, which is what we have long attached importance to. The new production model is the first in the industry to introduce a multi-axis machine tool process, combined with the workpiece replacement technology and gripper design developed by Twuhuolong, which further enhances the flexibility of automated products and the potential of the processing range. It can provide customized surfaces and various degrees of freedom processing, achieve ultra-high precision, extreme yield, and contain industrial-scale innovation and excellent standards.